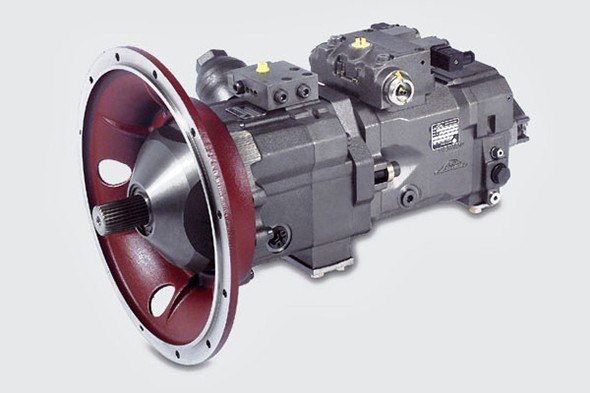

Double, tandem and multiple pumps

FOR OPEN AND CLOSED LOOP OPERATION

Set up by combining our variable displacement pumps and self-regulating pumps. They can either supply larger volume flows or feed different circuits.

The rated size and the type of the pump for open or closed circuits are variable. The sequential arrangement is determined by the maximum torque which can be transferred.

Due to their swashplate design our motors can also be combined to form double and tandem motors.

Design characteristics HPR double pumps

- two pumps of the same rated size, fitted back-to-back

- common port plate housing

- single or dual circuit

Design characteristics tandem and multiple pumps

- two or more pumps, fitted face-to-back

- open and/or closed circuit

- tandem pumps: Pumps of the same type

- multiple pumps: Pumps of different types

Product advantages double, tandem and multiple pumps

- only one drive shaft required

- no splitter box required for the pumps

- compact design

- individual control of each single pump

- no adverse influence on functionality of the single rotating groups

- advantages such as high dynamics and precise control remain in full

Design characteristics HMV double motors

- two motors of the same rated size, fitted back-to-back

- common ports for high pressure, servo-and control pressure

- can be controlled individually or together

- both motors can swivelled to 0 cc/rev

Product advantages double motors

- high conversion range for smooth acceleration

- simplified drive train

- high tractive effort and high final speed

- fast control response and high starting torque